-

-

Notifications

You must be signed in to change notification settings - Fork 26

shift

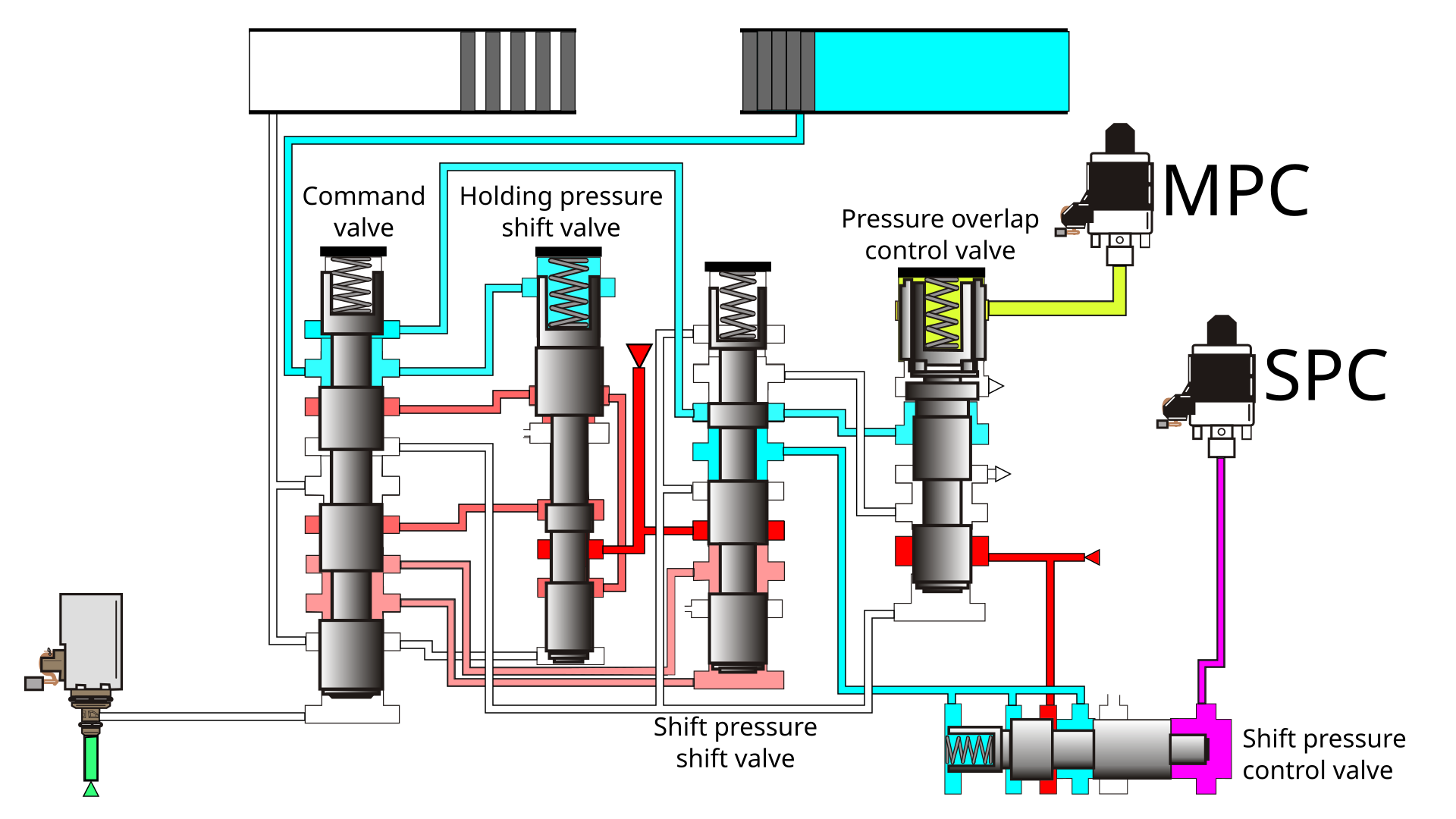

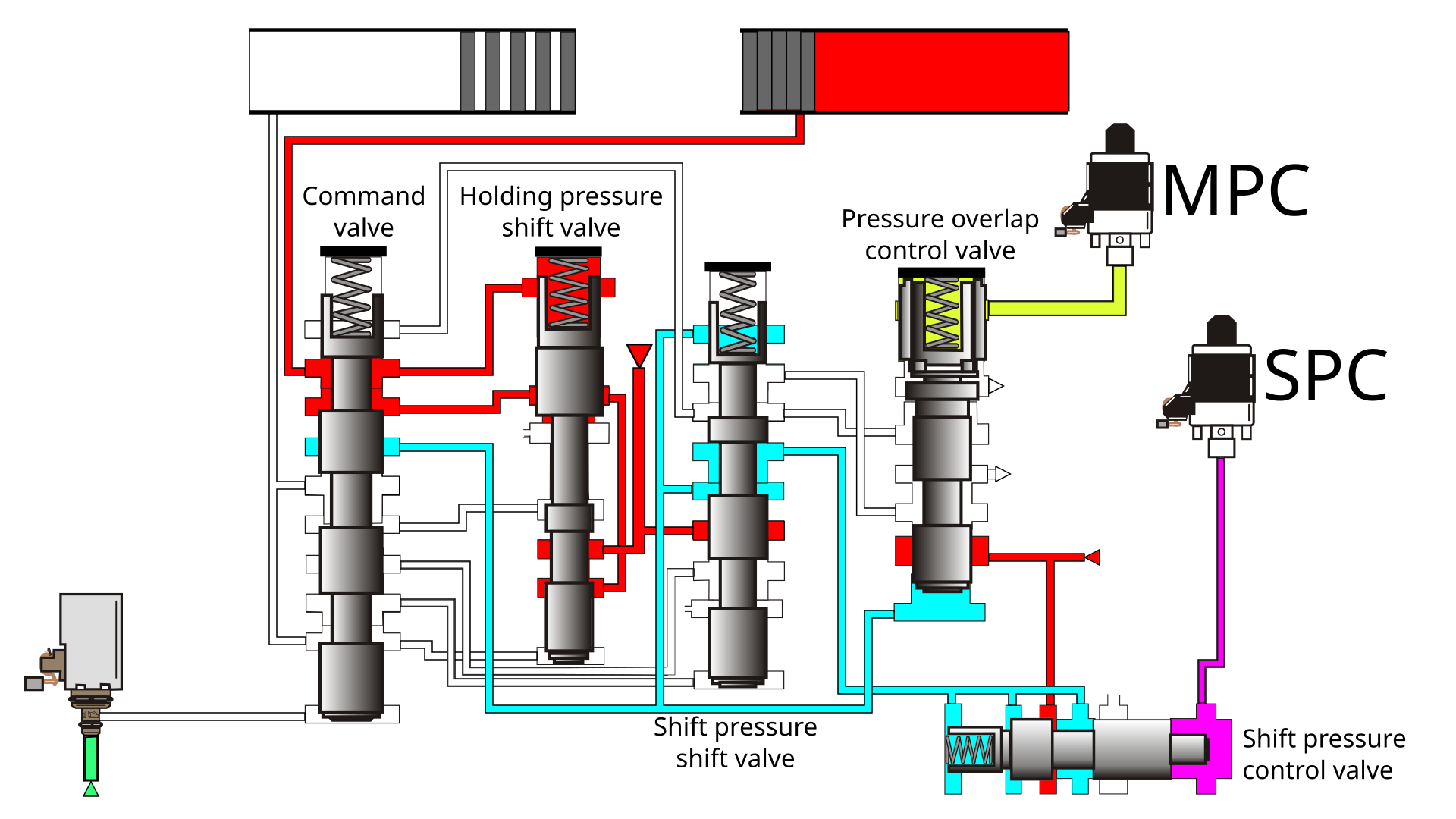

During each gear change of the 722.6 gearbox, the TCU will follow a 5 step process in order to maintain a smooth gear change. This 5 step process is required due to the complex inner workings of the hydraulic valve body of the gearbox.

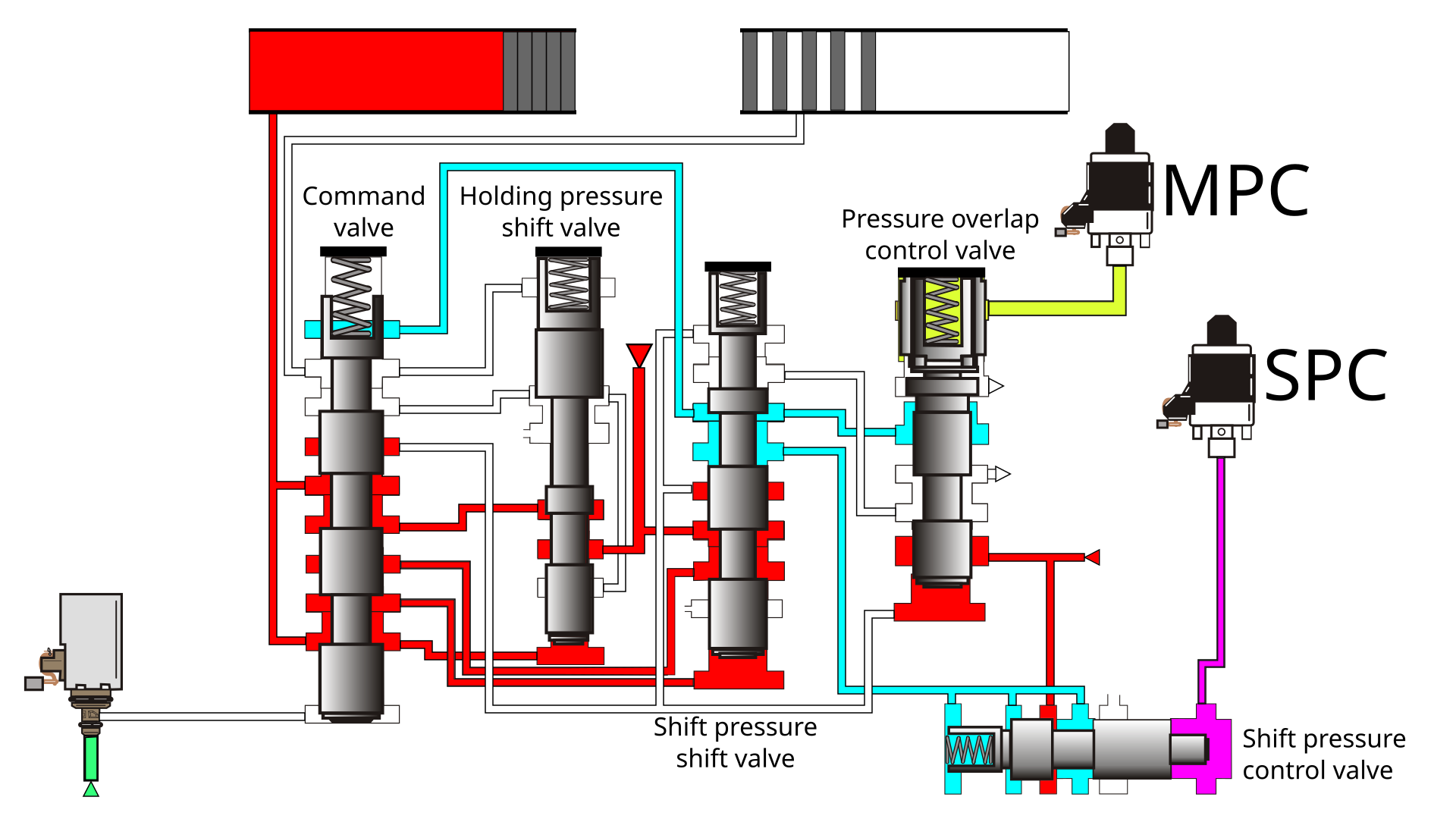

At the start of the gear change, the SPC solenoid will bleed to 50mBar of pressure. This will relax the pressure of the SP Regulatory valve in the valve body, which means when the shift is actually commanded, there is not a sudden in-rush of pressure to the clutches to be applied.

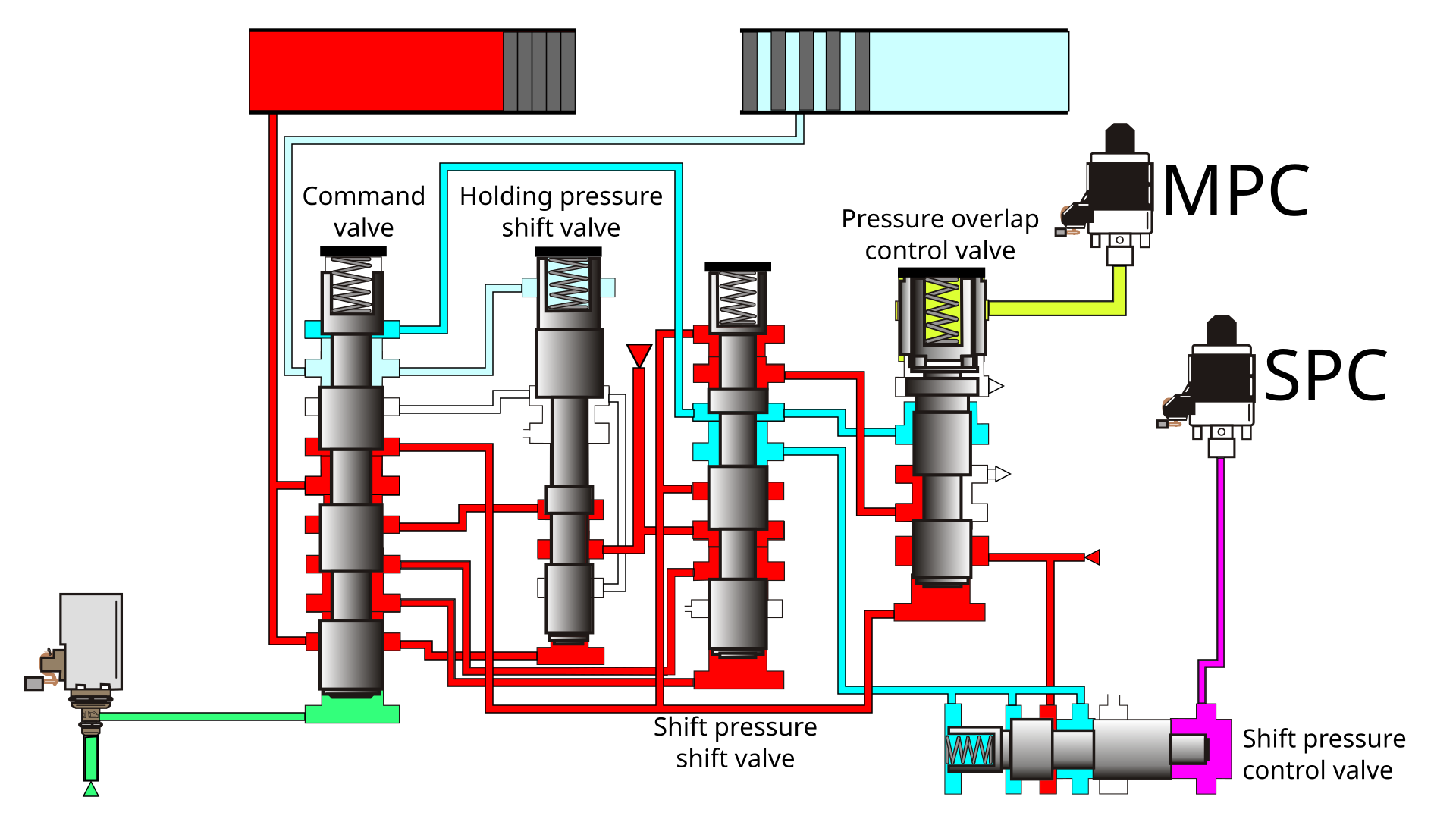

Next, the shift solenoid is opened, which will redirect pressure being produced by the SPC solenoid to the target clutch pack to apply for the next gear. The SPC solenoid will try and maintain a steady 650mBar of pressure in order to just fill the clutch drum with fluid, without moving the clutches.

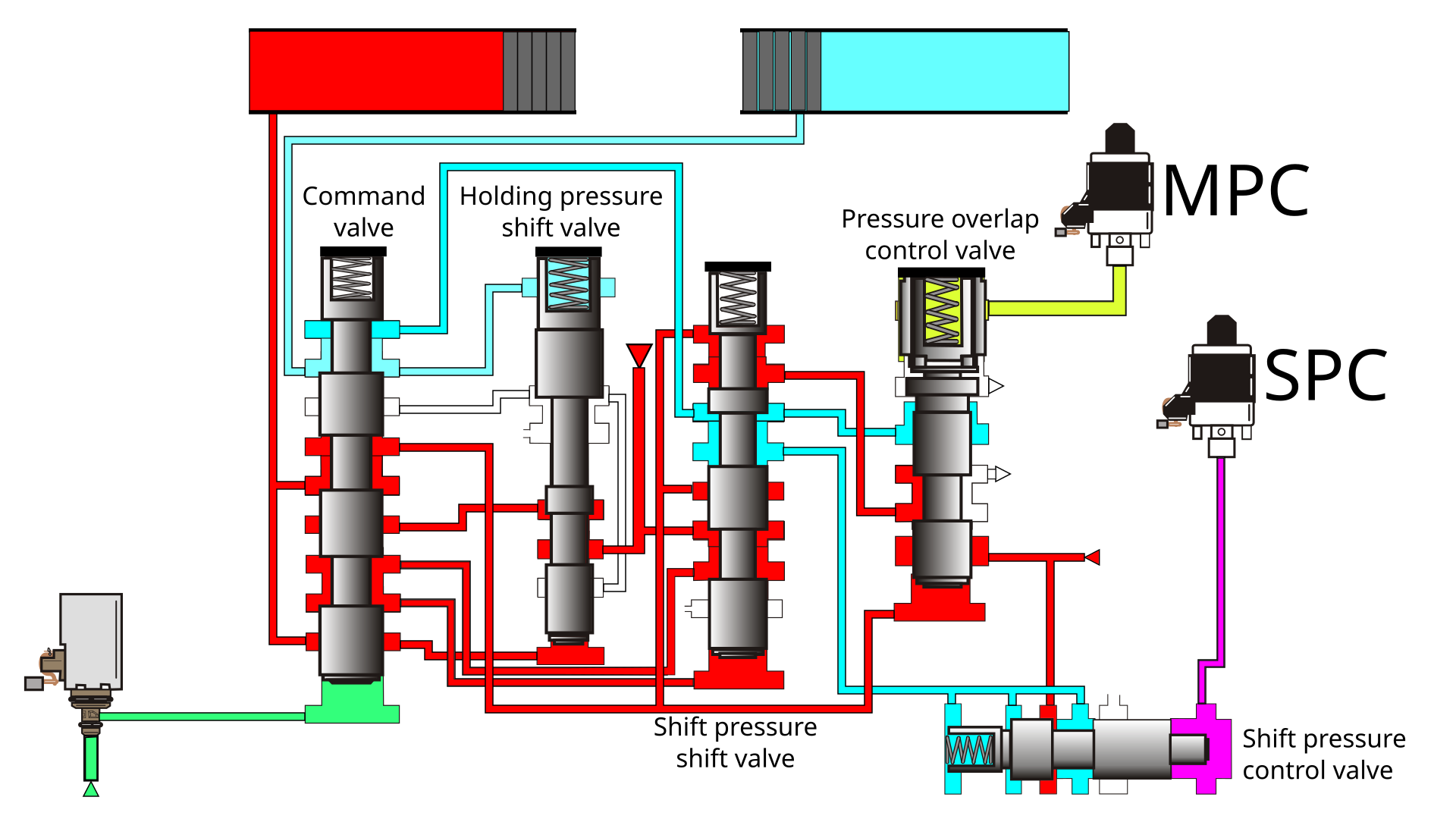

At this point, the SPC solenoid has filled the clutch drum of the target clutch with fluid. It now increases pressure to 1200-1500mbar (depending on the clutch pack), this now moves the clutch packs of the target clutch to a 0 tolerance clearance. This means the clutch pack is just about to be applied and there is no space between each clutch pad/plate.

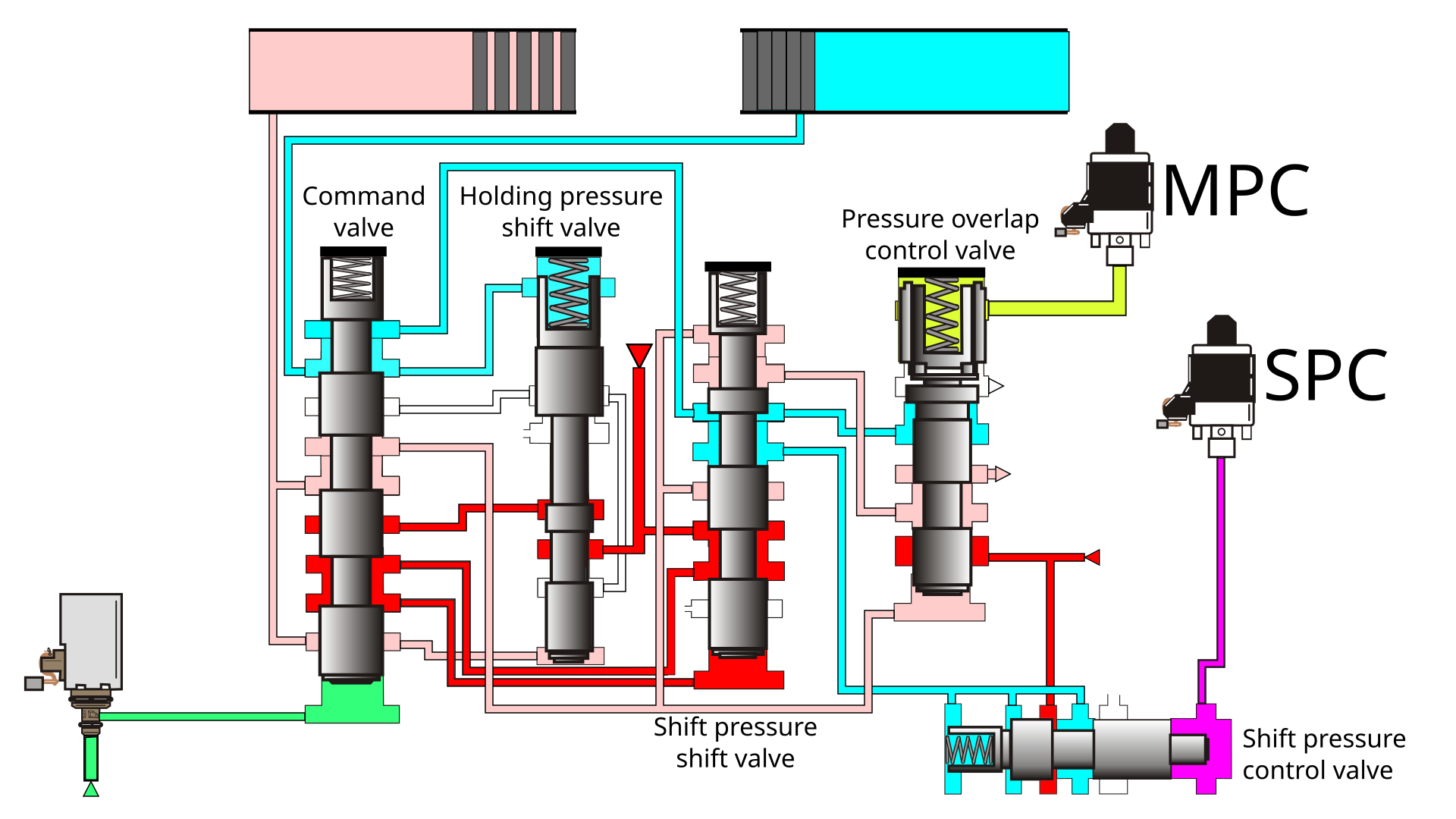

Now, the SPC solenoid will steadily increase pressure, moving the new clutches into position to take the torque of the old clutches. At the same time, the MPC solenoid relaxes a little bit to allow the old clutches to bleed pressure (Using the overlap valve in the hydraulic valve body to control the bleed rate). A smooth gear change occurs when the rate of the new clutches being applied matches the rate of the old clutches being released.

The most reported issues with the 722.6 gearbox are caused by shift flaring. This is when the gearbox appears to engage neutral for a split second during a gear change. This is caused normally by a worn out overlap valve. This means that MPC pressure is lost during the overlap phase, meaning the old clutches of the previous gear get released too quickly, BEFORE the new clutches being driven by SPC have a chance to be applied. Therefore, for a split second, there is no clutch being held in place.

In this last phase of the gear change, the SPC solenoid commands maximum pressure to lock the new clutches into place, then the shift command solenoid turns off in order to transition the new clutches to be fed by MPC pressure rather than SPC pressure.

<<GlobalTOC()>>